Our production line has 22 injection molding machines, with tonnages ranging from 1 to 450 tons. The machines can be used to manufacture objects up to 1.3 kilograms in weight. All of our machines are modern, and we are currently upgrading to fully electronic models, which are more accurate, faster, more energy efficient, and so forth. Our injection molding line runs non-stop all year round, which guarantees maximum capacity and output.

Our machinery

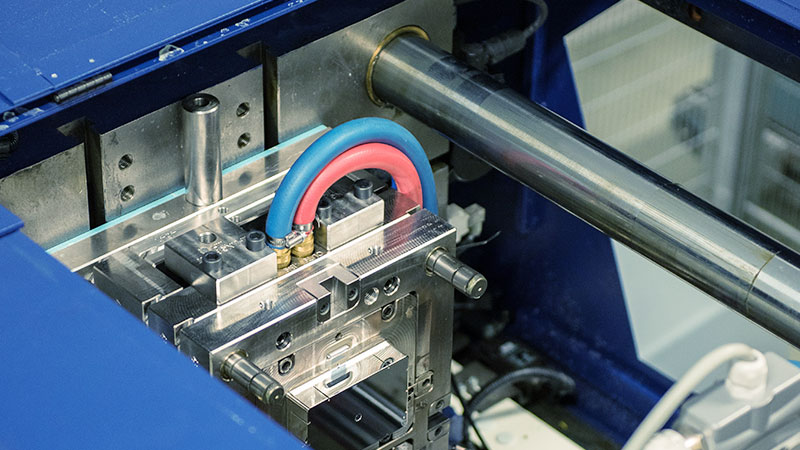

IMD & IML

Our facility has IMD (In-Mold Decoration) equipment. In the IMD method, carrier foil gets run through the mold, and the image on the foil is transferred onto the product. In IML (In-Mold Labeling), the foil is placed directly inside the mold before injection molding begins. This is usually done with robotics, when the robot removes the finished product at the end of the previous cycle. With these two methods, we can manufacture very aesthetically pleasing products.

Insert molding

In insert molding, objects, such as metal parts, are placed inside the mold and attached to the plastic product during injection molding. This makes it possible, for example, to insert bolts into the product so that they are a fixed part of the finished plastic product.

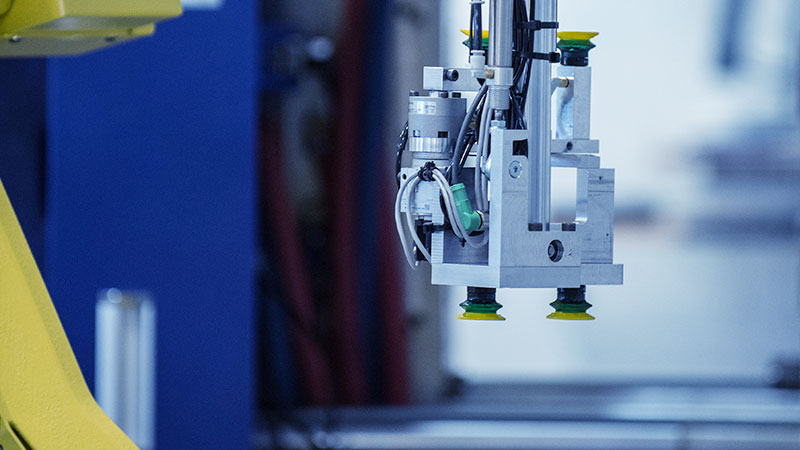

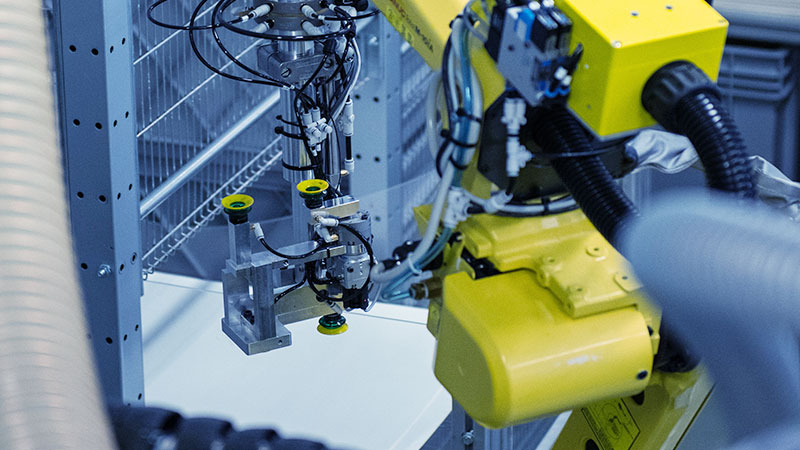

Automation

Our injection molding line consists of 12 integrated robotic cells, which make it easy for us to handle injection molded objects after they are removed from the mold. Automation can be implemented in assembly, marking, packaging, sorting, or in other value-adding activities. We mainly design and build our production automation, which makes for a very competitive service package.

25 years of plastic product manufacturing

All about plastic

We provide a full production chain for your products. Our services range from design and development to storing finished products. In many cases, an injection molded product is not ready to be sold without further processing. We can, for example, assemble products from multiple components, mark your products, or conduct functionality tests on your products.