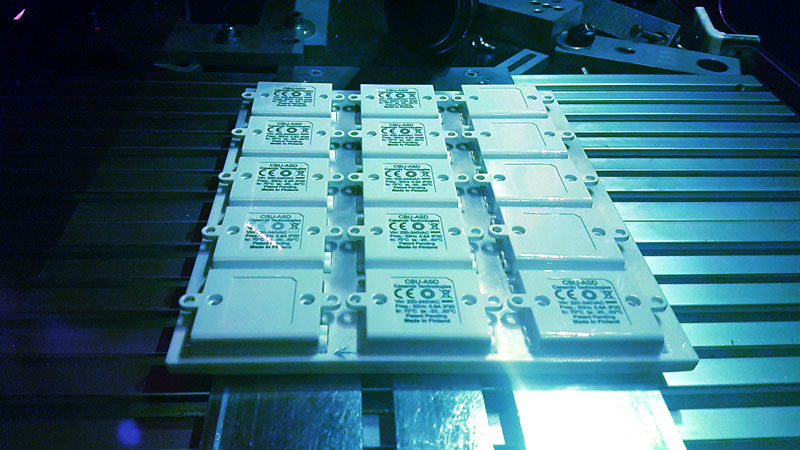

Laser marking can be used to add a finishing touch to the product, for example, in the form of logos, instructions, and other similar markings. The marking is very precise, and it stays on the product unless it’s sanded off. The laser is a quick and efficient way to mark plastic products.

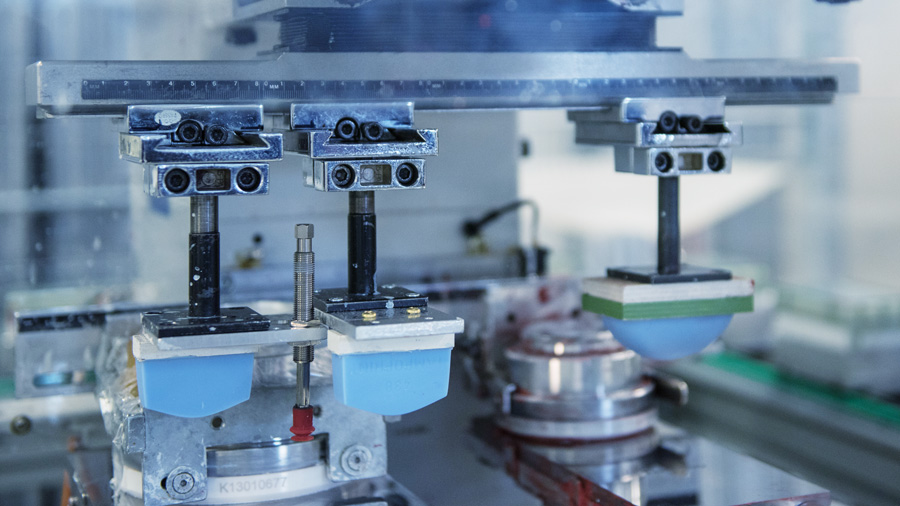

Pad printing allows us to put markings also on curved surfaces, and these markings can contain several different colors. Our production line includes two pad printing cells with 6-axis robots there to handle printing. Additionally, we have four hand-operated pad printing machines.

We have the capabilities to carry out various product assembly tasks. Assembly work is done both by hand and with robots. Purchased components and multipart assemblies can be produced efficiently because we utilize first-rate manufacturing execution systems.

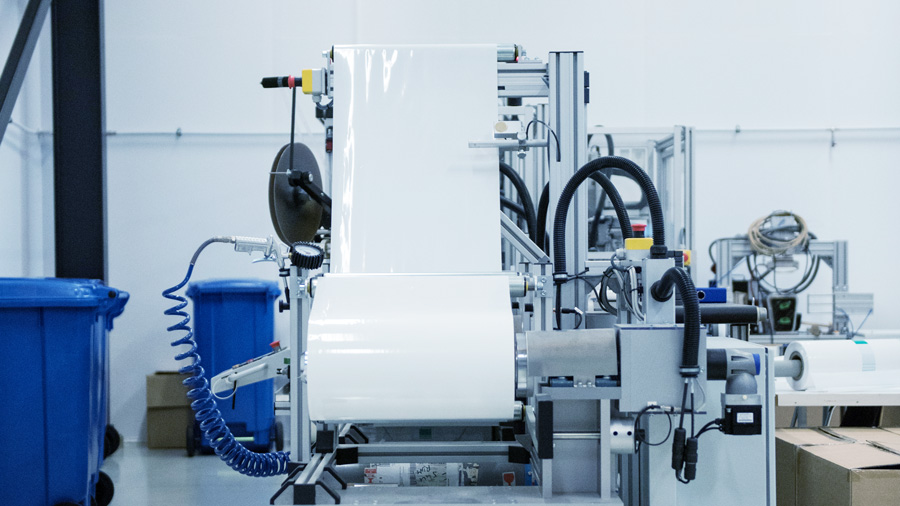

We have four machines that we use for ultrasonic welding. Depending on the project, these machines allow us to weld injection molded objects and also plastic film.

All about plastic

[/ultimate_heading]

We provide a full production chain for your products. Our services range from design and development to storing finished products. In many cases, an injection molded product is not ready to be sold without further processing. We can, for example, assemble products from multiple components, mark your products, or conduct functionality tests on your products.